W:three

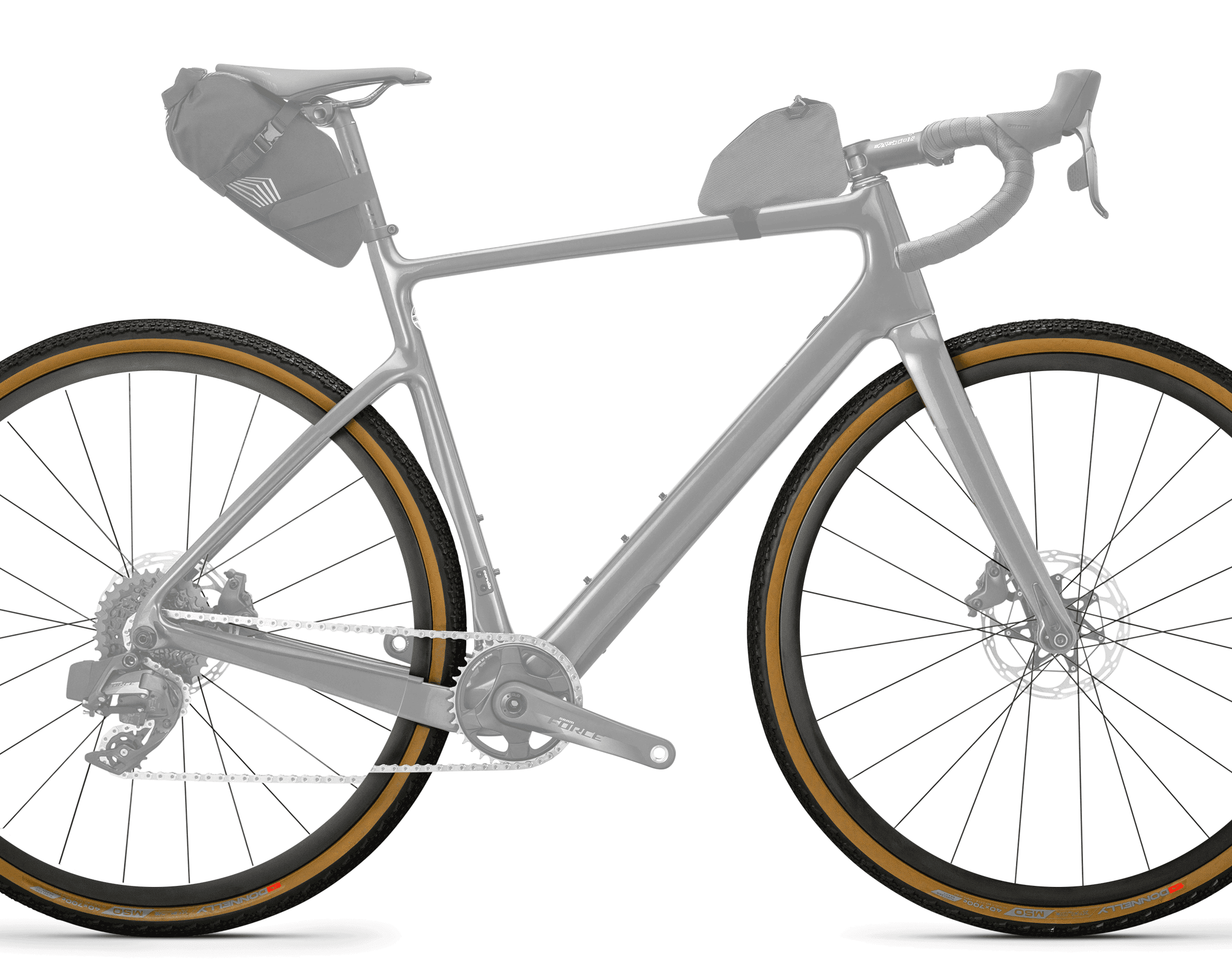

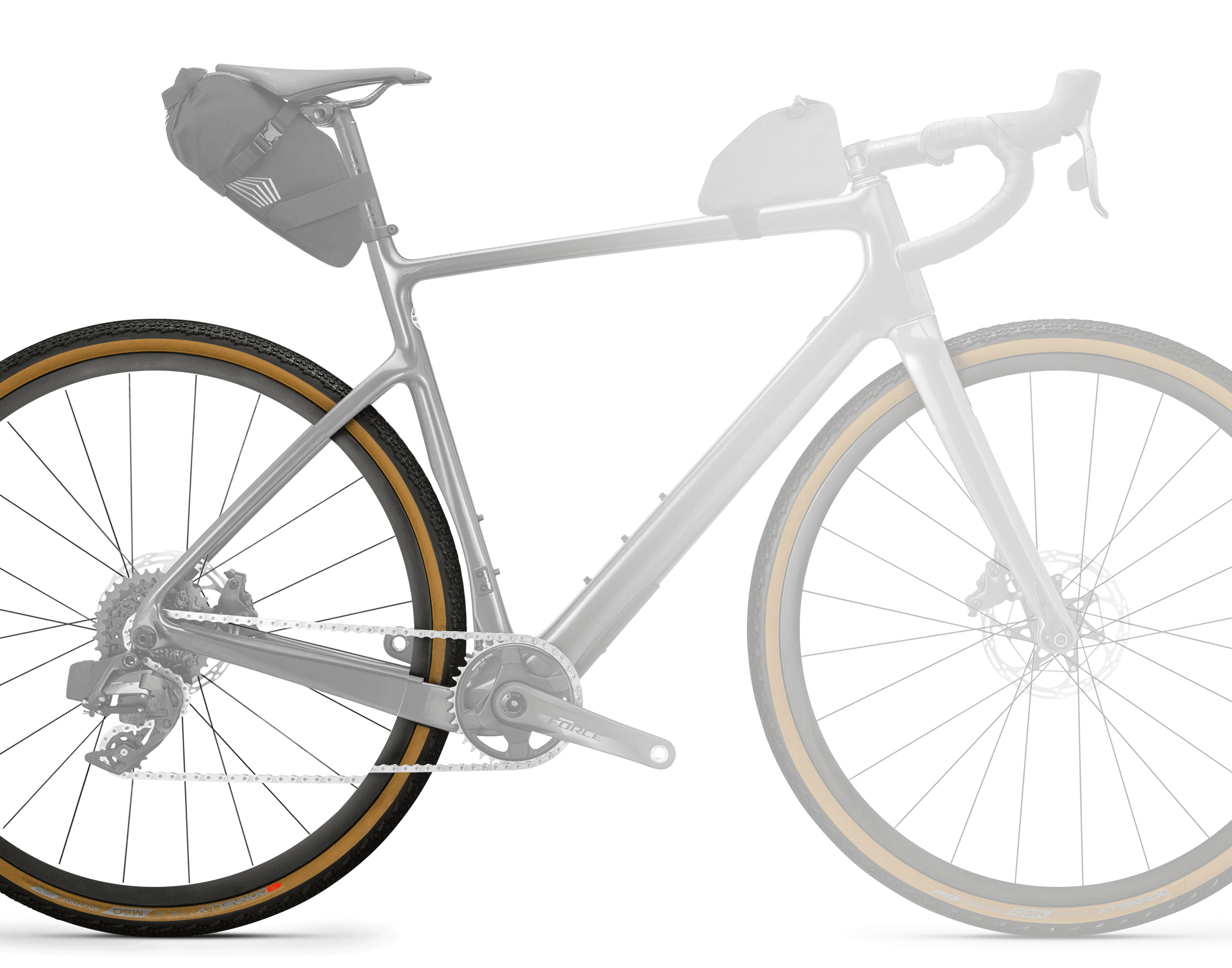

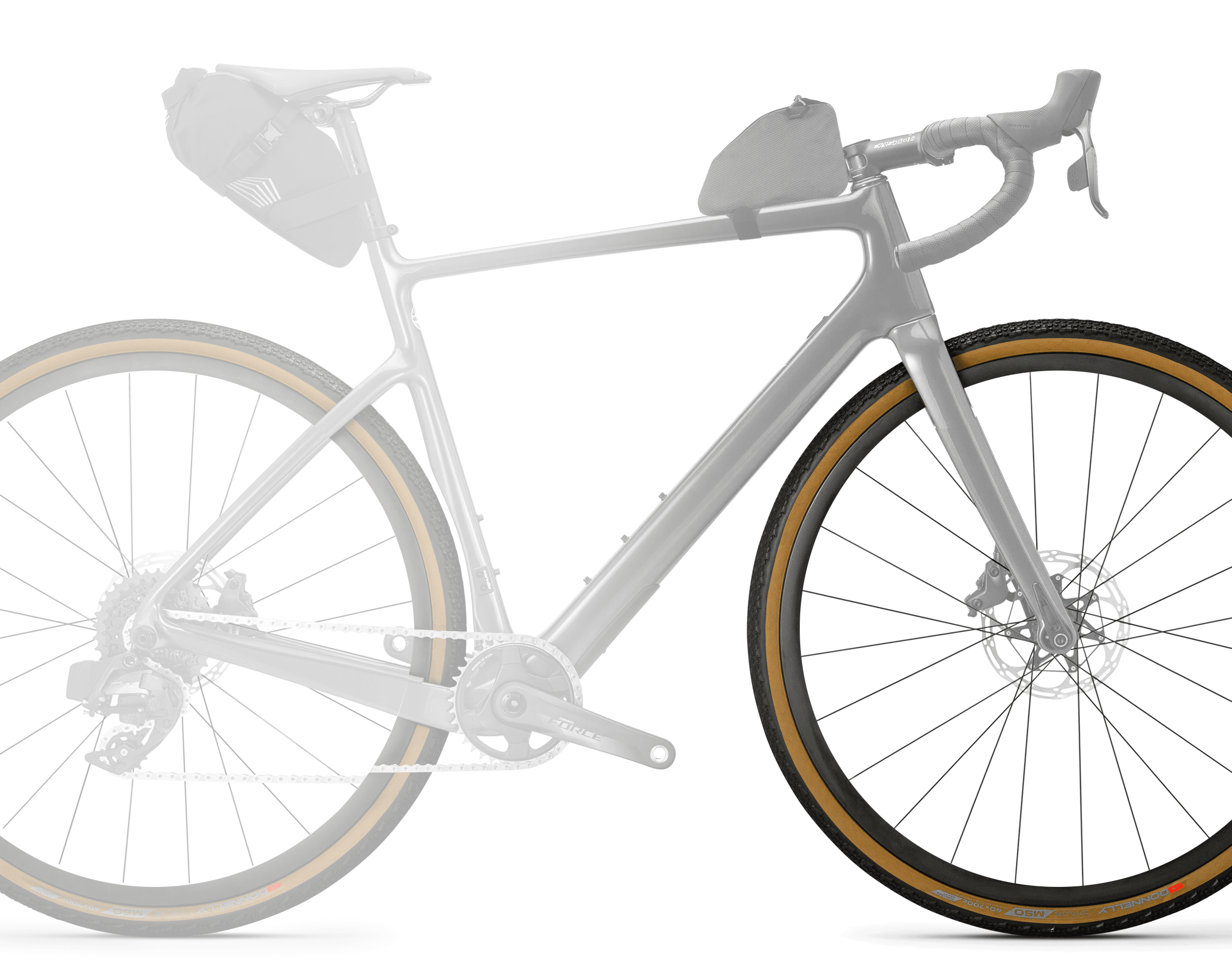

W:three is a 30mm-internal width wheelset designed for gravel and bike-packing adventures on all surfaces.

Use this Builder to customise your own wheels. Buy online or speak to a friendly sales rep. Don't worry if you're not sure - after you place an order we'll call you and talk through the choices you've made to ensure everything is correct!

We set out with 4 keys goals when designing the W:three

- Match the performance and durability of the gravel and bike-packing wheels on the market.

- Surpass those wheelsets in long-term serviceability, ease of maintenance, and ability to fit a wide range of bikes.

- Simplify the buying process by offering a careful selection of high-performance options that deliver exactly what you need and nothing you don't.

- Deliver all of this at a competitive pricepoint.

In the Box

Your new W:three wheels arrive pre-taped and fitted with high-flow tubeless valves, ready to ride straight out of the box.

Tracked courier delivery is free of charge in New Zealand and Australia.

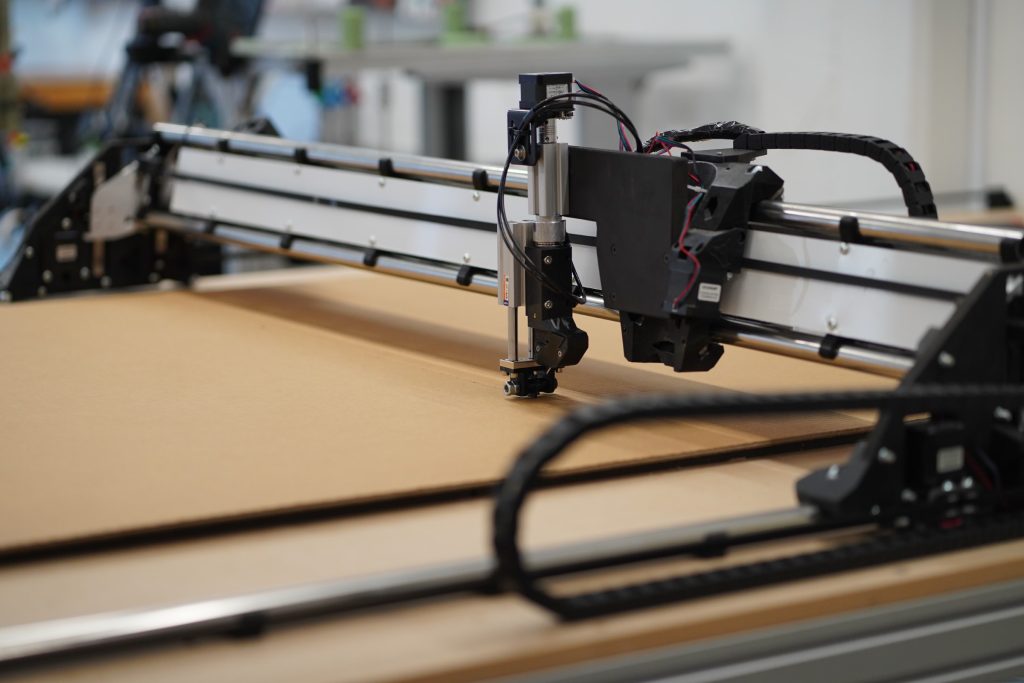

Your wheels will be securely packaged in a custom-made cardboard box, produced in-house on our CNC. The twin-cushion cardboard is made from 68% to 71% recycled material, with the remaining pulp sourced from sustainably managed forests in Kawerau and Tokoroa. The shipping box is designed for multiple uses and is fully recyclable.

We’ve eliminated single-use plastic, styrofoam, and unnecessary ink from our packaging to reduce waste while ensuring your wheels arrive safely.

Component Specifications

Built for Long-Term Performance

Every component has been carefully tested against industry leaders, both on the trail and in our test fixtures, to ensure it meets our exacting standards.

These wheels are designed for long-term serviceability and ownership. Every W:three wheel is individually built in New Zealand to Wheelworks' meticulous quality standards and backed by a warranty and rim replacement deal, ensuring lasting performance and easy maintenance.

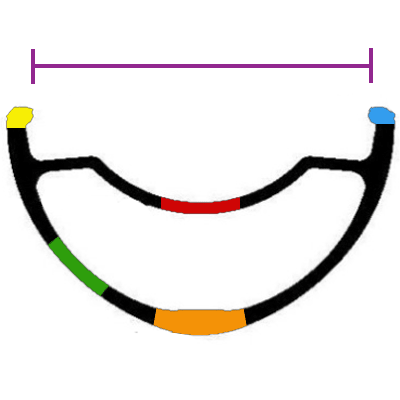

Rims

A 30mm internal width rim for gravel cycling offers increased tyre support, allowing you to run wider tyres at lower pressures for better comfort, grip, and stability. The broader profile improves sidewall support, reduces tyre squirm, and enhances vibration dampening, helping to minimize rider fatigue on long rides and rough "roads".

With an unloaded bike, lower tyre pressures improve traction on rough trails. When carrying bikepacking gear, the additional rim and tyre volume help maintain control, comfort, and stability over extended distances.

A hooked bead design increases safety and ensures compatibility with a wider range of tyres. Hooked beads allow for higher tyre pressures, making them ideal for extended paved sections—just be sure to stay within your tyre’s maximum pressure rating. Unlike hookless rims, there’s no need to check a compatibility chart—the W:three works with all tyre models.

When designing our W:series wheelsets it was important for us to benchmark our new rims performance against what we know to be the best rims in the industry. Our impact test fixture played a key role in this.

Unlike impact testing on the W:one and W:two, where withstanding high-energy impacts is a key consideration, the W:three is designed to endure repeated medium-energy impacts. This simulates the demands of long-distance gravel riding and bikepacking—where a fully loaded bike encounters continuous vibrations, potholes, and rough terrain over extended periods.

In these tests W:three rims are among the most durable aluminium rims we’ve tested, outperforming competitor options in both lab and real-world conditions. Our rigorous testing, both in the lab and in real-world conditions, has shown that the W:three rims not only withstand these stresses but excel in long-term durability. Riders carrying heavy loads over rugged terrain can trust these rims to maintain their integrity ride after ride.

The rim is joined using advanced bonding technology, which enhances strength, improves impact resistance, and ensures a perfectly sealed tubeless-ready joint. This is a new technology which is superior to traditional pinning or welding as it ensures an accurate, fully tubeless-sealed joint without introducing localized heat warping to the rim.

Each rim is laser-engraved with your unique wheelset number and spoke lengths, making it easier to track, service, and replace parts when needed—so you can keep riding without hassle for years to come

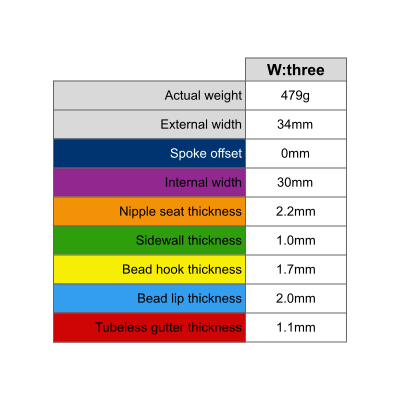

Hubs

The Dial hub has proven itself to be durable and reliable but what often impresses owners the most is its ability to be easily serviced without any special tools.

Gravel bikes are the wild-west of axle "standards" and the Dials highly modular design allows it to fit an incredible number of the axle types the industry uses ensuring compatibility with your current bike and, likely, your next one.

- Available in Centerlock and 6-bolt rotor options.

- Freehub compatibility: XD, HG, Microspline, and Campagnolo N3W with options for 36t and 72 engagement points.

- Exceptional service website

- All small-parts available

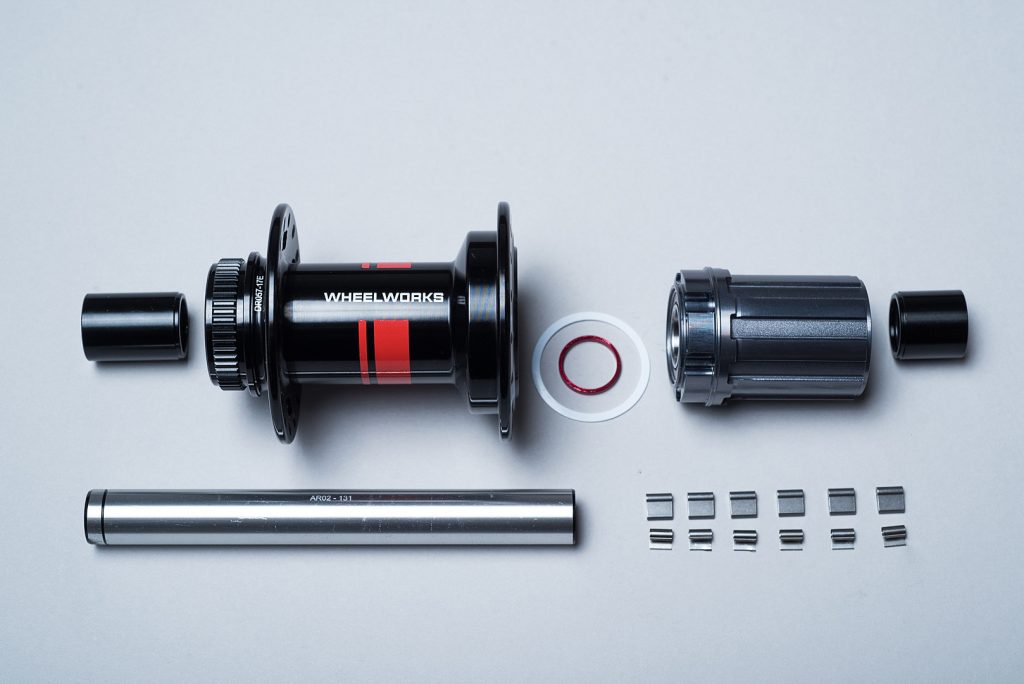

Spokes

The Alpina Extralite Round, produced in Italy, is a double-butted spoke measuring 2.0mm at the head and thread, tapering to 1.7mm in the center. Alpina’s unique two-stage cold-forming process strengthens the spoke head significantly, making it up to 30% more durable than other brands. This results in a spoke that better withstands high-tension loads, improving longevity and reliability in demanding riding conditions.

For convenience, spoke lengths are laser-engraved onto the rim, ensuring quick and precise replacements when needed, reducing downtime and simplifying maintenance.

Spoke Nipples

We use Sapim Polyax Secure Lock nipples, produced in Belgium, for their durability and reliability. These corrosion-resistant nipples ensure long-term performance and make re-truing easy, even after years of riding. The Polyax head features a ball shape that improves alignment inside the rim, reducing stress at critical points and minimizing the risk of spoke breakage.

High Flow Tubeless Valves

W:three wheels come equipped with our high-flow tubeless valves, designed to enhance ease of use and long-term performance. These valves feature:

- No-clog head to prevent sealant buildup and maintain airflow.

- Removable head for effortless seating of stubborn tyres.

- Fully rebuildable for long-term reliability and serviceability. Each sub-component is available individually.

- Slotted base for full compatibility with tyre inserts,

Weight

A W:three rim is 479 grams. Wheelset weight gets complicated on custom wheels as different hub models and freehub body types weigh different amounts.

A W:three with 100x12mm front and 142x12mm rear hubs and an XDR freehub body will weigh 845g front and 980g rear, including tubeless tape and high flow valves.

If you need a weight for another hub or freehub body combination please get in touch.

Easy to Maintain

We’ve chosen high-quality, proven components and built them with long-term ownership in mind.

- Brass nipples, grease on spoke threads, and laser-engraved spoke lengths ensure easy maintenance.

- Each wheel has a unique engraved wheelset number, allowing us to assist with upgrades or rebuilds when switching drivetrains or bikes.

- These small details make a real difference in durability, but they’re nearly impossible to spot for the untrained eye.

Accidents Happen

The truth is, any aluminium rim will dent if hit hard enough. The design, material choice, and construction method all influence how well a rim withstands impacts. Unlike carbon rims, which crack under extreme force, aluminium rims dent or flat-spot.

Using our impact test rig, we’ve verified that W:three rims outperform the best aluminium wheels on the market by maintaining their structural integrity under repeated high-impact forces. They resist deformation, retain tubeless integrity, and exhibit less damage compared to competitor models, ensuring long-term reliability on the toughest trails. We test the W:three model up to 150 Joules of energy, simulating the toughest adventures and roughest backcountry terrain.

Extensive real-world testing by our ambassadors confirms these lab results. Riders have pushed these wheels through rugged backcountry gravel, loaded bikepacking expeditions, and rough washboard descents. The feedback has been overwhelmingly positive—exceptional durability with minimal maintenance required.

The W:three model is built to handle the toughest adventures and the relentless impacts of rough gravel roads, unexpected potholes, and fully loaded adventures while maintaining its integrity ride after ride.

Warranty

The W:three wheelset comes with a 12-month warranty covering manufacturing defects, material issues, and workmanship. Our thorough wheelbuilding and QC processes ensure any potential problems are caught before the wheels leave our workshop.

The maximum system weight (bike + rider + bags) for the W:three is 130kg.

Rim Replacement Program

In the unlikely event you damage a W:three rim, we offer a heavily discounted rebuild program to keep your wheels rolling without breaking the bank. This ensures that long-term ownership remains cost-effective, providing peace of mind for riders tackling tough terrain. While exchange rates and global trade conditions may affect future pricing, we are committed to keeping costs as low as possible for our customers. This offer is valid for two years for the original owner and is non-transferable.

- $190 for a new rim and 32 spoke nipples for self-rebuild.

- $310 for us to rebuild your wheel with a new rim and spoke nipples.

Legendary Wheelbuild Quality

A well-built wheel stays true for longer, withstands more punishment, and remains easy to service, ensuring reliability ride after ride. Build quality is what transforms good components into exceptional wheels.

For us, good wheelbuilding means a blend of expert craftsmanship, custom-written software, and purpose-built tools, all working together to create the highest-quality wheels. For over 19 years, we've been committed to perfecting every detail—measuring, testing, and continuously improving. We've developed proprietary processes and designed our own specialized tools to ensure every wheel meets our exacting standards.

Production and Country of Origin

Rims: W:three rims are produced in Taiwan

Spokes: Alpina spokes are fabricated in Northern Italy

Spoke nipples: Sapim spoke nipples are produced in Belgium

Hubs: Dial hubs are produced in Taiwan

We custom build each wheel in our Wellington workshop

End of Life

Aluminium rims, hub shells, stainless steel spokes and brass nipples are all recyclable at your local metal recycler, or you can return these materials to Wheelworks for recycling.

The cardboard shipping carton can be kerbside recycled

Find out more

If you need any help understanding whether the W:three is the right wheelset for you please call us on 04 387 3592 or email sales@wheelworks.co.nz

Location: Central Otago, NZ