DT Swiss 240 Ratchet DEG deepdive

Overview

This is a deep dive on the DT Swiss 240 Ratchet DEG hub. We’re going to cover the technical elements but also my honest views on both the new hub and DT Swiss by talking about what you won’t read in the press releases.

History

Bear with me because to really understand the new hub we need a history lesson on the older ones

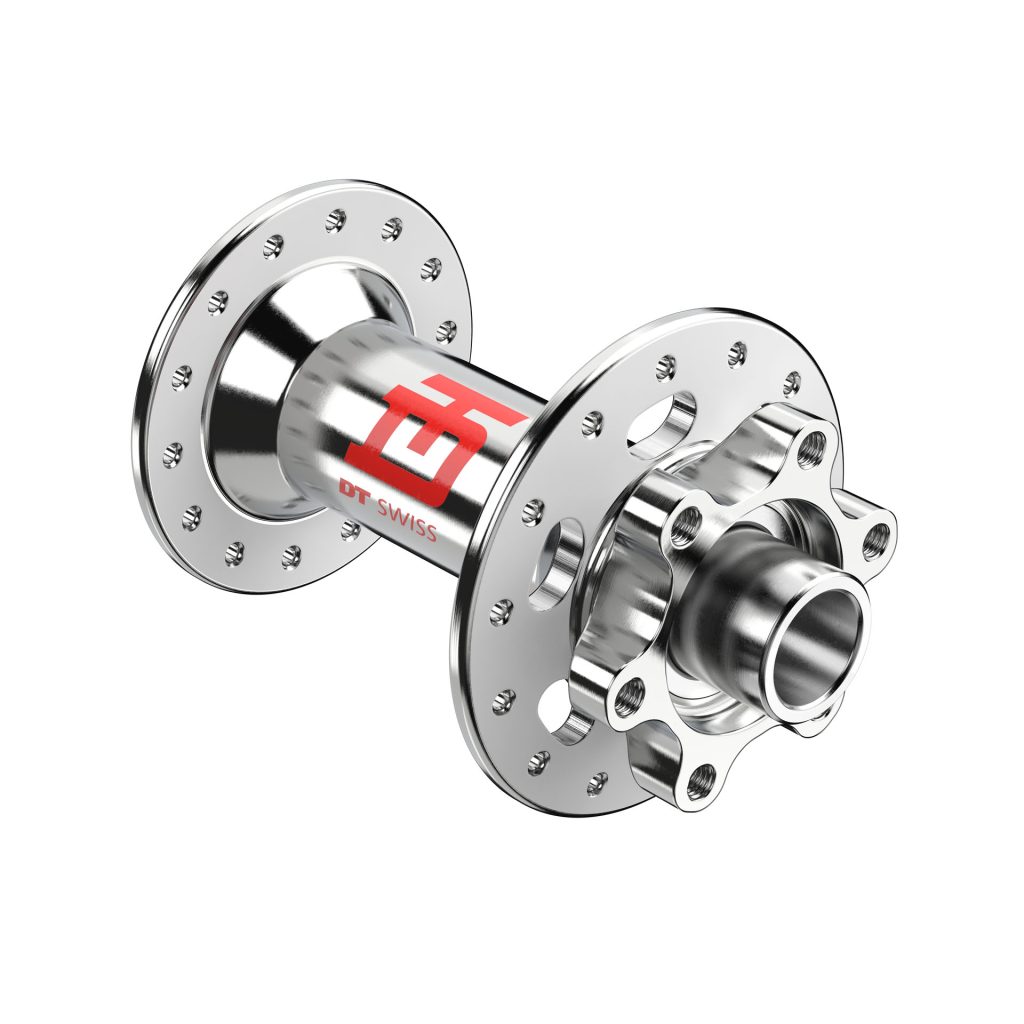

As recently as 5 years ago DT Swiss really only sold two hubs - the cheaper 350 and the more expensive 240 and there wasn’t much difference between the two. Both used the now famous system of two clutch plates, now called “Ratchet” and all parts were completely interchangeable between the two with the only difference being more machining on the more expensive 240 to save weight

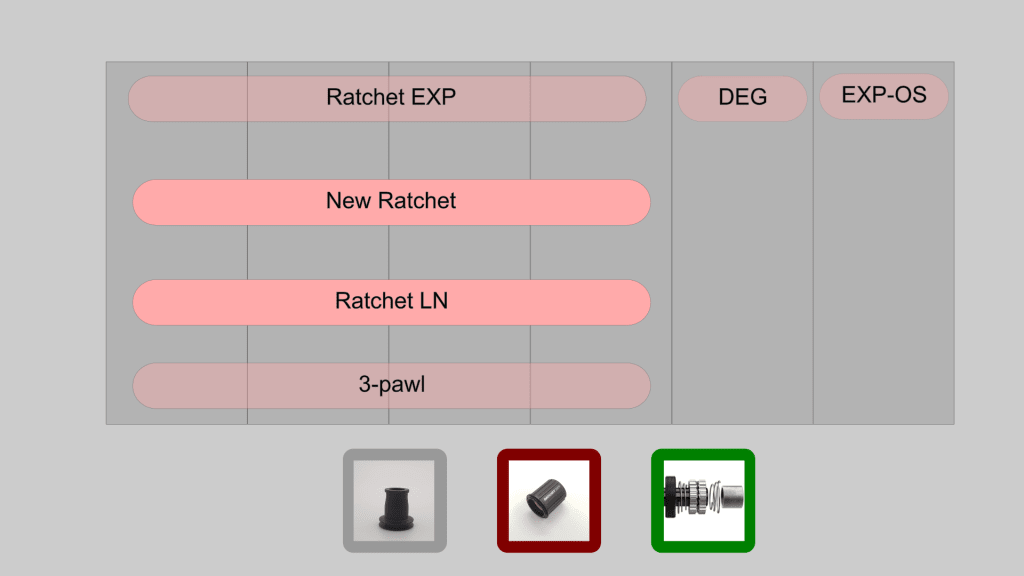

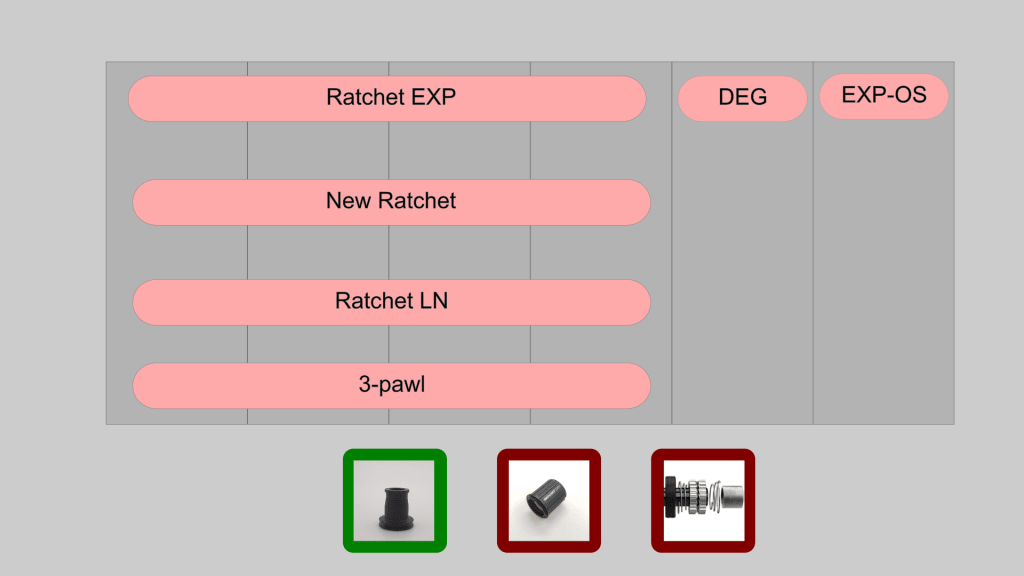

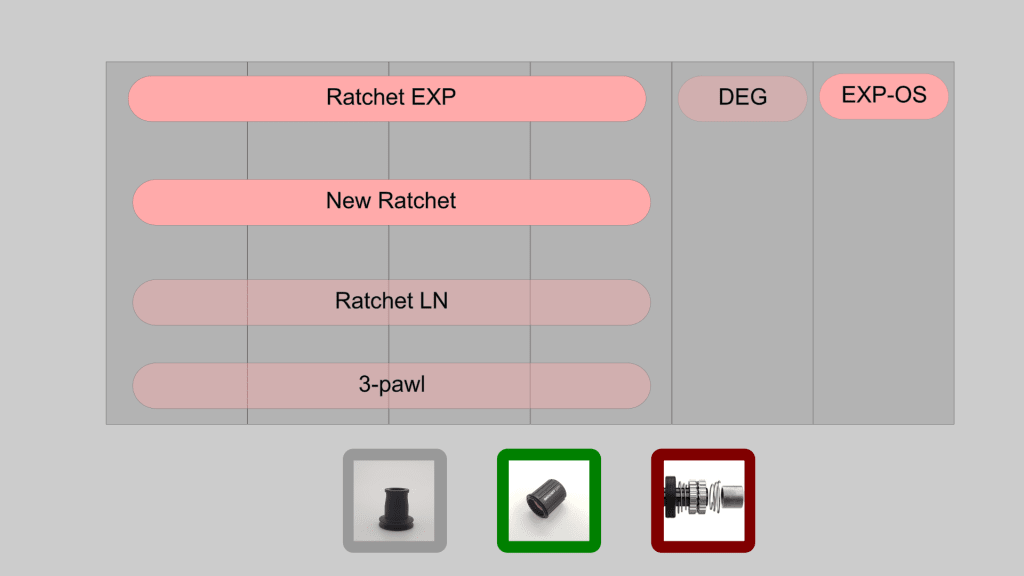

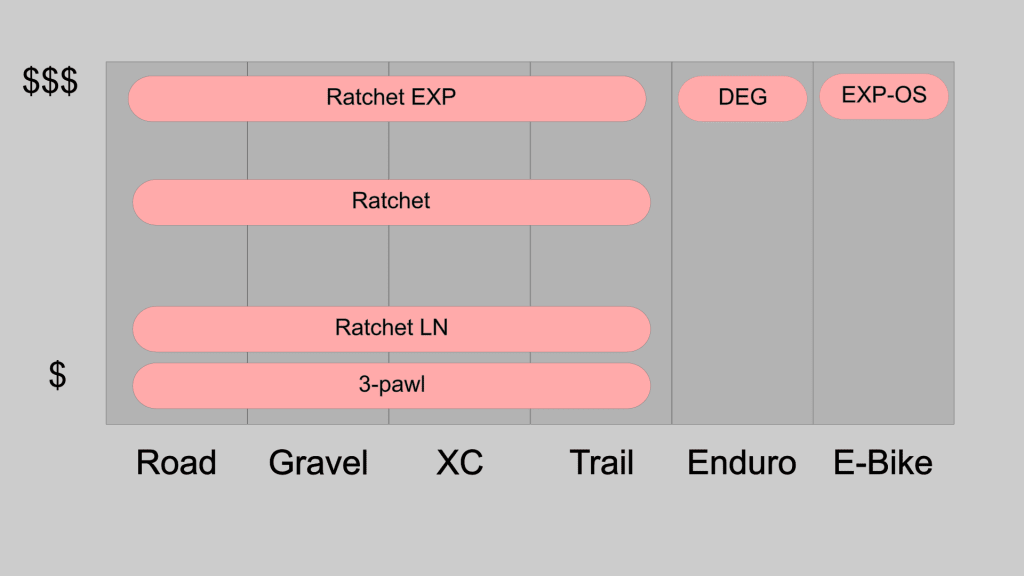

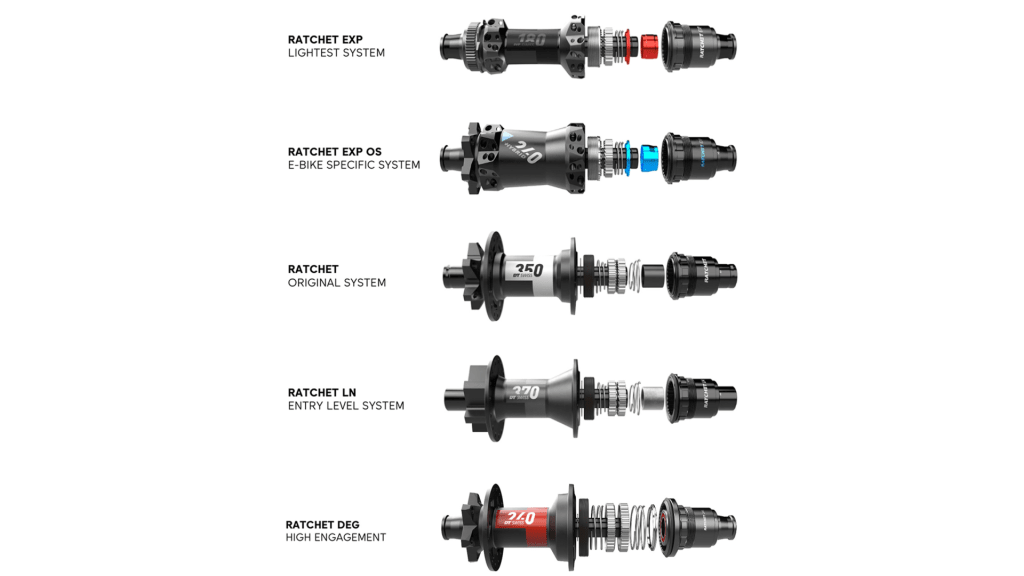

But a lot has changed in that time. DT introduced the low end 3-pawl 370 then the Ratchet LN drive system, they upgraded the 350 to be much more like the old 240, they introduced the Ratchet EXP drive system, then the Ratchet EXP oversized system, and now the Ratchet DEG drive system

Most of these hubs share the same endcaps, some share the same hub internals but not freehub bodies, others the same freehub bodies but not hub internals

So what used to be a very simple product range is now broken up, with DT’s goal being that each niche of cycling has its own model of hub, at different price points.

And the Ratchet DEG has arrived to fill that All Mountain / Enduro niche. DT Swiss do not specifically recommend the DEG hubs for e-bike but the use is not excluded.

It’s currently only available at the 240 price level but my guess is that we’ll see a 350 priced version within a year.

Big Changes

The major change is taking the star ratchets that DT Swiss has become famous for and making them much, much larger to allow for more engagement points

Rather than maxing out at 54 points of engagement the new Ratchet DEG comes with 90. For slow, technical mountain biking having a faster engagement hub is a real improvement.

Caution

Honestly, I’m approaching the Ratchet DEG hubs with optimism but caution. The classic DT Swiss Ratchet hubs have proven themselves to be one of the most durable hubs on the market and have excellent bearing life, but the more recent Ratchet EXP was plagued with issues at launch, and even once those were fixed the bearing drag and bearing life can leave a lot to be desired.

The launch of the Ratchet DEG was delayed by around 6 months, which could be for any number of supply chain or engineering issues, but it does mean a rocky start when I’m sure DT Swiss were hoping for a smooth launch.

Will Ratchet DEG take DT Swiss back to the top of the rankings, in an increasingly competitive market? The durability of a new product is always unknown, and is only a question time can answer.

Options

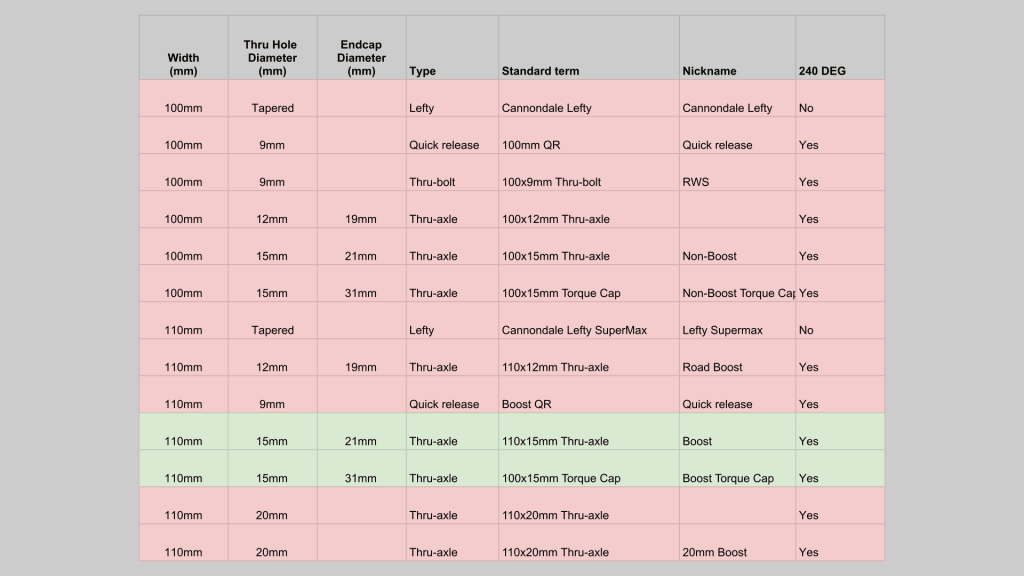

240 Ratchet DEG hubs are only available in a 6-bolt rotor mount, and only with J-bend spokes.

Front hubs are available only in 110x15mm Boost, with a Torque Cap endcap option, and rear hubs are only available in 148x12mm Boost or 157x12mm Super Boost. Hubs are either 28 or 32 hole.

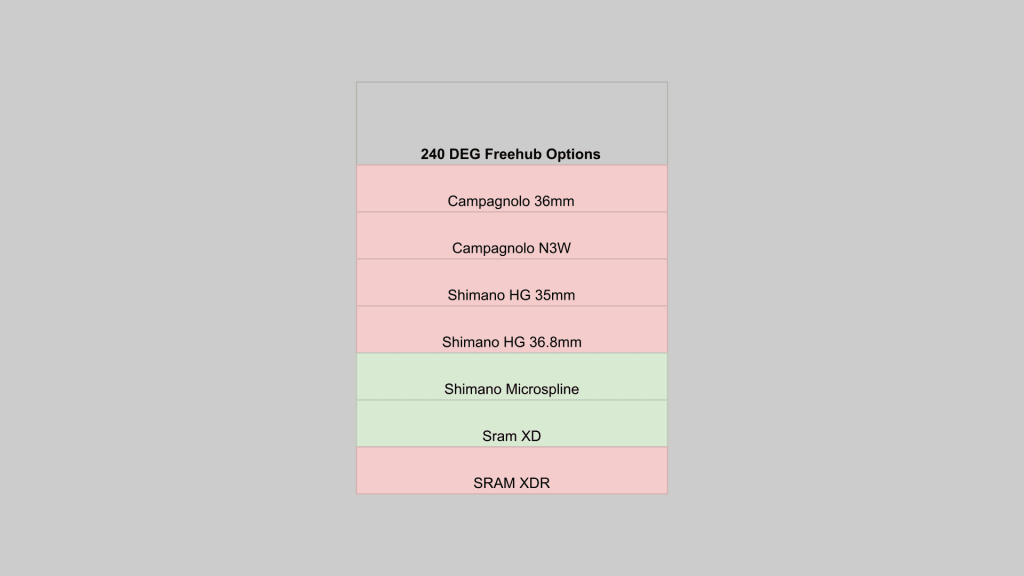

DT Swiss Ratchet DEG compatibility options

It’s worth noting there is no HG freehub body option, only XD and microspline, so these will only work with the more expensive cassettes from Sram and Shimano

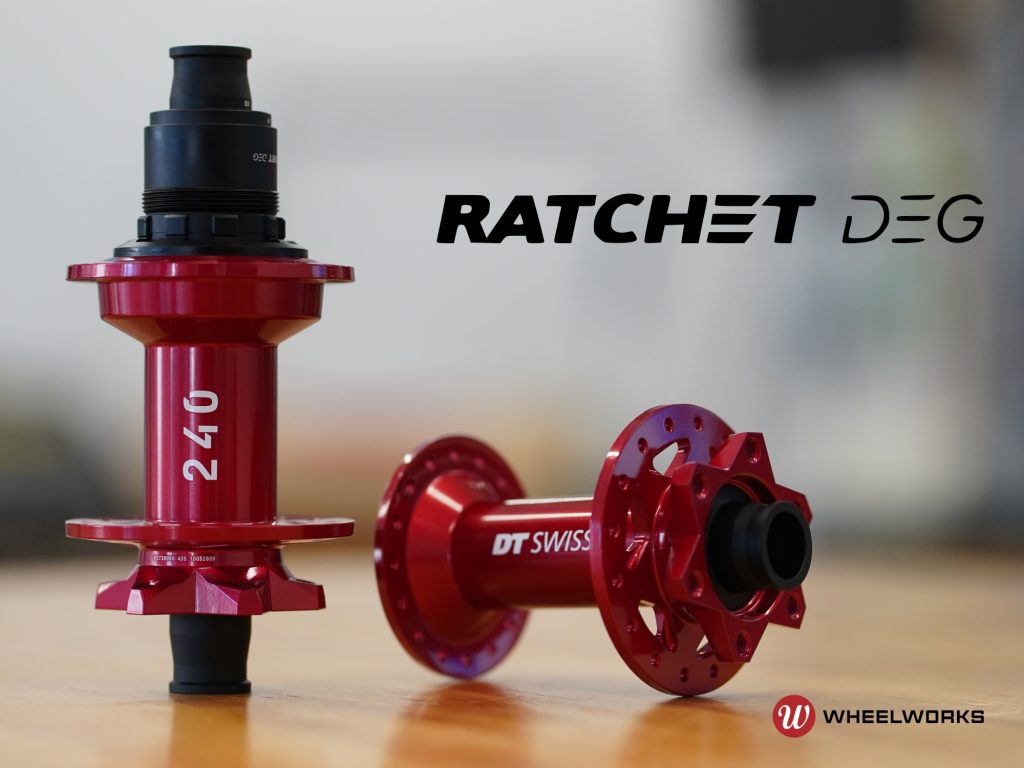

Production hubs are matte black with red bands and look very similar to other hubs in the DT Swiss range. Durability of this newer coating has been a really good improvement from the older painted hubs.

240 limited pairs of red

At launch they also offered a limited edition glossy painted red version with white text which will look absolutely lovely on the right bike, and with only 240 pairs of these offered worldwide they’ll no doubt be a collectors item, although the thick, glossy paint will almost certainly chip with time.

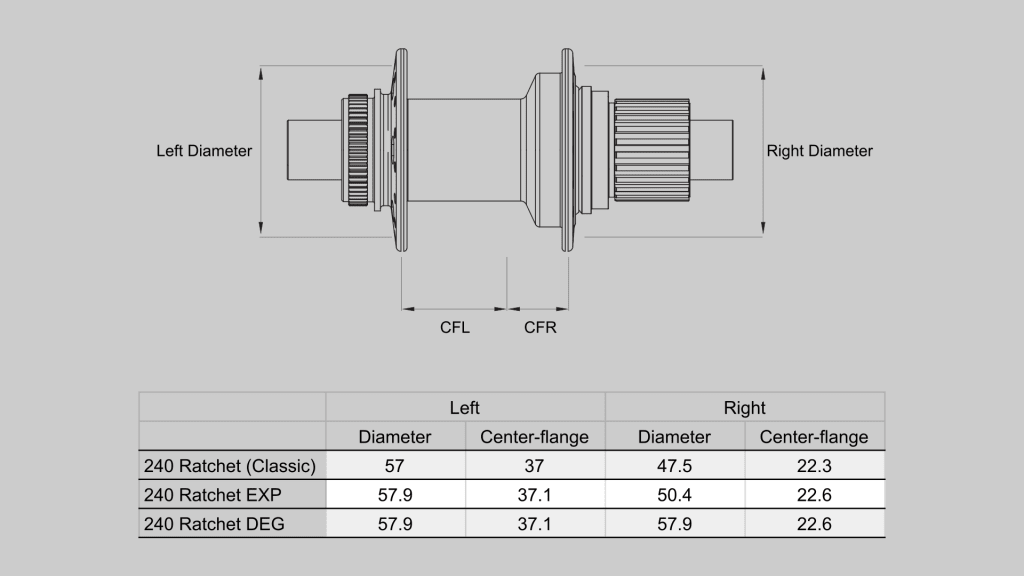

Flange dimensions

A few years ago light weight, big-diameter 29 inch aluminium rims meant flange geometry made a noticeable difference to wheel stiffness, however in today's modern world of Boost hubs, and wider aluminium and carbon rims our test data shows very little real-world difference.

But with that said, while the non-driveside flange is in a similar place, the driveside flange is larger than both the older Ratchet hubs , and the EXP hubs, so the wheels lateral stiffness will be slightly higher, which is a good thing for the type of riding this hub is designed for

Pulling it apart

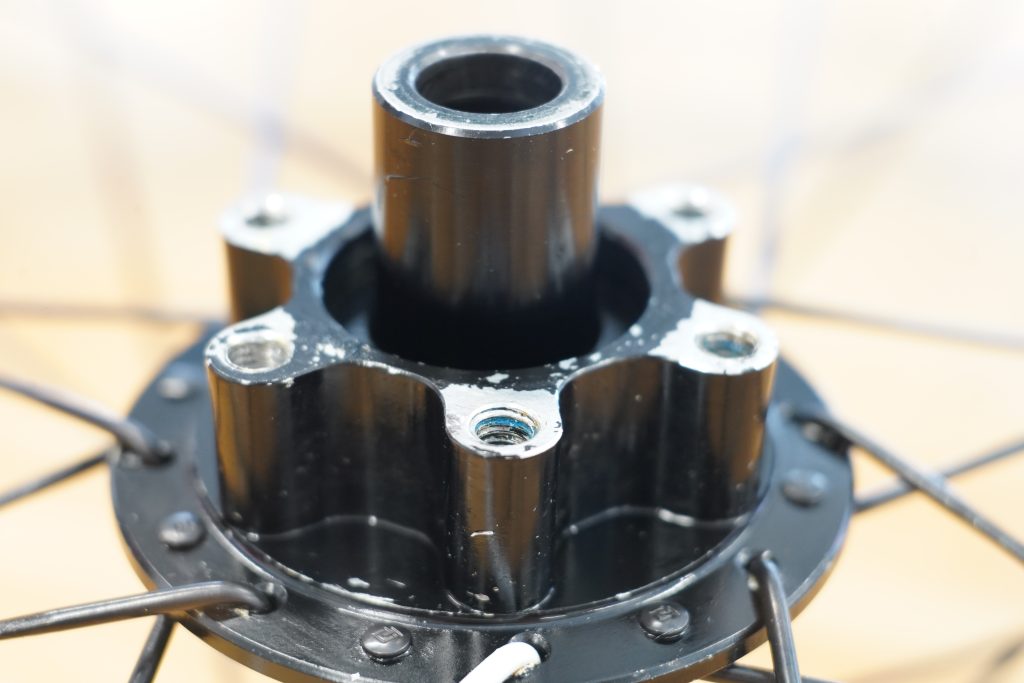

What is compatible with other hubs? The endcaps - nothing else. Thankfully these use the same endcaps as almost every hub in the DT Swiss range, although with each freehub body type requiring a different driveside endcap, and with endcaps being offered in gloss black, gloss black with this ridge, matte black, and matte black with this ridge there are a lot of chances to get confused.

They go to the effort of laser etching the freehub body type onto the endcap, which is great, but it would be even better if they said what axle type it’s for or ideally write an easy to use part number.

Endcaps are friction fit using a standard N70 o-ring, and its little known that these are easily replaced if you have problems with endcaps falling off.

Once we pull it apart the most obvious thing are these large ratchet rings. You can certainly see the family resemblance to the other DT Swiss models but these internals are significantly larger and therefore not interchangeable.

unlike Ratchet EXP where one side is threaded into the hub, each DEG ratchet has its own spring. Unlike the tapered spring design of the Ratchet hubs, which we often see installed backwards, these are symmetrical.

Also like other DT Swiss hubs the ratchets are flat. I believe this is one of the contributing factors for the early EXP issues as when your axle flexes the ratchets’ ability to contact each other is reduced. As the DEG ratchets are larger, this is potentially more of an issue.

On other models of DT Swiss hub there is a thick aluminium spacer separating the hub and freehub body, but on the Ratchet DEG this is just a tiny shim. If you’re familiar with White Industries hubs it’s the same half millimeter thick DIN988 washer, and honestly I’m not a big fan of this setup as tiny hub internals tend to get lost or damaged easier than larger ones.

The freehub bodies are not interchangeable with any other hubs in the DT Swiss range. It’s a shame to see the seal permanently attached to the freehub body and not a replaceable part as this is what causes a lot of the drag issues we see on other models of DT hub.

Ratchet DEG uses the same super expensive grease as the rest of the DT range. It’s supposedly a “high pressure” grease which works better when squished, but honestly it works really well and most of the time when we see DT hubs with chipped internals they’ve been using an off-brand grease, so I think it’s worth the money.

By oversizing all the internals two really important features are opened up:

First -if you have ever serviced a Ratchet or Ratchet EXP hub will know you need to remove the threaded ring to access the driveside hub bearing, and these can be bloody hard to remove as it tightens into the hub as you pedal.

No more! On the Ratchet DEG hubs the driveside bearing can be removed easily! Whew!

Secondly the extra space means the driveside bearing is moved outwards by about 2.5mm compared to a classic Ratchet hub, but is still 2mm narrower than the EXP. This gives the bearings a wider stance than a Classic hub, which should lead to both better bearing life and fewer broken axles, but interestingly is narrower than EXP.

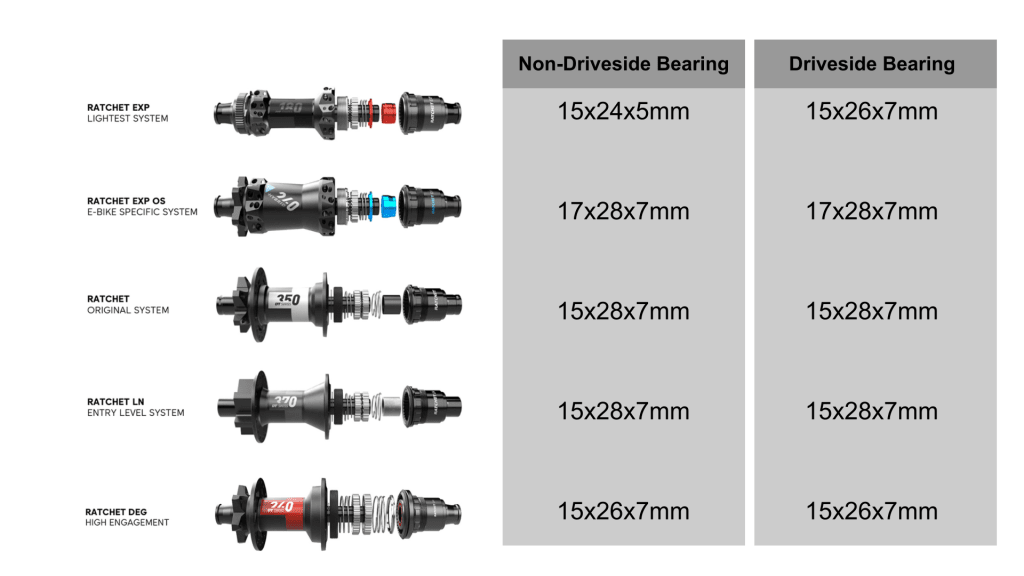

Speaking of bearings, the 240 DEG uses a steel 15x26x7mm bearing on both sides of the hub. This is the same bearing which is used in most of the EXP model hubs, which aren’t renowned for their bearing durability, and is smaller than the 15x28x7mm bearing used in the traditional Ratchet hubs.

Servicing

DT’s Tech docs have always been really good, and the DEG is no different with good exploded parts diagrams and good service instructions

Combine the excellent instructions with the new design not requiring the threaded ring to be removed to replace the bearings, and the DEG hubs are super simple to service.

I did get a chuckle at the techdoc saying how pedalling tightens the ring nut, and therefore it requires a “high force to loosen”. This little tidbit is missing from every other DT Swiss hub manual where the threaded ring is required to be removed to service the bearings, and is one of the major complaints of that design.

The tech docs also have some tips on how to inspect the ratchet rings for wear and when to replace them. People often don’t treat DT Swiss ratchets as consumable parts, but this is a good reminder that they are.

Conclusion

Look, I'm on the fence at the moment as to whether DT Swiss are heading in the right direction here. I think the mountain bike market wants one hub which can do everything by being modular and interchangeable. For our customers this is the big selling point of Hope Pro5s, Dial hubs, and OneUps new hubs. DT seems to be heading in the opposite direction by making a different platform for every type of riding.

However, the DEG hub looks very well made. The extra engagement points are great and the ability to easily service and replace bearings is fantastic.

I feel like the pricetag is pretty high and I can’t help but think that a 350 priced version of these will be really popular.

The hub market is becoming increasingly competitive and DT Swiss are stepping it up with the DEG. Is it enough?

-Tristan